产业4.0的来源,概念与架构

Industry 4.0 (I4.0) evolved from a German government initiative and associated working group. At the heart of industry 4.0 there are 4 principles :Interconnection via the Internet of Things(IoT)/Industrial internet of Things(IIoT), Information availability across the production process facilitating analysis and action, Automation and facilitation of decision *** and provision of Cyber Physical Systems(CPS) to complete tasks best suited to machines rather than people(ideally autonomously).

产业4.0最初由德国当局提倡,产业同盟合作推动,涵盖4年夜要害技巧要素:

物联网(IoT)

产业物联网(IIoT);

出产环节与出产举措措施,出产剖析,与现实运营之间的信息及时互通

从帮助人完成义务,改变为帮助机械完成义务。具备主动与简略单纯化的决议计划链与数字化实体出产运营体系(CPS),以最顺应机械的方法,完成出产义务,比人工更精准。这就是超主动化(Gartner 2020年十年夜计谋技巧趋向陈述中也有说起)

From these principles a range of constantly evolving and changing technologies are available for organisations wishing to benefit from the Industry 4.0 revolution. They share some common characteristics and are typically grouped together as:-

Data and analytics technologies (Big Data) collection and interpretation of data from a range of sources with the desired aim of *** consistent, correct, proactive decisions. Includes the concept of cognitive computing.

Smart factory/production technologies including use where appropriate of robotics devices. The objective of these technologies is to drive seamless, environmentally responsible self-optimising processes and systems that realise best in class production performance.

Cyber physical systems (CPS) integrations of computation, networking and physical processes e.g. robotics systems, manufacturing control systems. These cyber-physical systems also build and maintain a Digital twin of the physical world.

The internet of things (IoT-consumer)/Industrial internet of things (IIoT) i.e. the mobile, virtual and persistent connection of all devices to the internet and each other.

Interoperability development of standards, processes and systems to allow all participant stakeholders and organisations to share information effectively.

所有盼望从产业4.0受益的企业或组织,都可以遵守并实现上述仍在不竭进化与更新的4年夜要害技巧。依据4年夜要害技巧特色,以下是业内助士分享的具体可落地技巧,涵盖:

年夜数据剖析 收集并说明各类起源的数据信息,确保目的一致的、正确的、瞻前的决议计划,包含认知盘算的技巧

智能工场(出产体系)- 包含恰当应用机械人技巧。目标是实现无缝、环保、可自立优化体系与流程,可以或许最年夜限度包管出产结果

数字化物理出产运营体系(CPS)- 整合了盘算单位、收集、以及物理出产流程(好比机械人体系,出产把持体系等)。这些CPS也是树立并保护数字孪生(Digital Twin)的基本

IoT(民众花费市场)与产业物联网IIoT, 好比移动互联网,各类终端装备、出产机械之间虚拟可是牢固平安的互联互通(经由过程互联网)

互操纵性 开辟可以让所有好处相干人、企业、组织都能介入并互操纵的尺度、协定、流程与体系。(小编按:实在就是为制作企业从私有产业物联网,转型财产物联网平台做预备,美国产业物联网几家倡议公司就预备形成财产物联网平台)

The current pallet of Industry 4.0 technologies includes but is not limited to mobile devices, advanced human machine inte***ces, 3D printing, drones, Smart sensors/PLM technology, traditional DCS systems, Digital Twin solutions, blockchain offerings, Big data analytics and advanced algorithms (e.g. failure prediction and preventative maintenance automated scheduling), Augmented reality/ wearables, improved ERP and CRM offerings. SD-WAN technologies for managing the complexity and rapid changing characteristics of IoT/IIoT networking requirements.

今朝可用于产业4.0各项技巧,包含但不限于移动装备、进步前辈人机交互界面、3D打印、机械人、智能传感器、智能PLM技巧、传统DCS体系、数字孪生、区块链、年夜数据剖析、各类进步前辈算法(如灾害预警,预防保护主动排班体系)、可穿着虚拟加强(AR)、更完美的ERP/CRM等技巧。而SD-WAN或进化版技巧,可管控IoT/IIoT庞杂互联互通与之间各要素快速切换时所须要的高机能收集需求。(小编按:如A平台装备须要B平台数据支撑,同时须要C平台决议计划链,须要调遣多个平台的数据剖析、ERP/CRM、装备、流程治理、人机互动、移动装备等多种要素,如斯互联互通的庞杂性与及时性,对收集通连的请求很高)

At the business level Industry 4.0 concepts will deliver business value by driving digitalisation and integration of value chains, driving production costs down, facilitating digitization of product and service offerings and finally developing digital business models that improve customer value. The bottom-line result will be connected customers, empowered employees, efficient production, improved products with improved operability and bottom-line profit.

产业4.0,经由过程数字化与价值链整合,可以以多种情势带来贸易价值:出产本钱降落,体系举措措施数字化带来的产物与办事个性化定制,终极形成数字经济,晋升用户价值。最要害的是,这条价值链衔接客户、更年夜自立权的企业人员、高效出产、更完美的产物,并晋升企业可操纵性与净利润

This report explains how Industry 4.0 related capabilities can be applied to specific energy industry use cases.

这篇陈述,重要论述产业4.0相干才能若何利用在具体的能源场景。

Use case: Industry 4.0 realisation facilitated by InfoQuickTechnologies Traditional upstream oil and gas

实例:产业4.0利用在传统石油能源行业

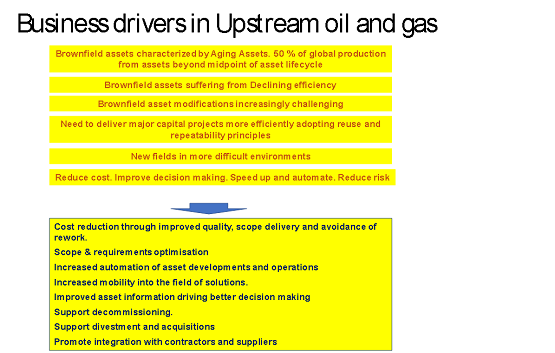

Business Drivers

Figure1Oil and gas business drivers

石油能源行业的营业驱动力

全球至少50%的在出产油田已颠末了其性命周期的中点,而这类油田出产效力慢慢下降,相干的进级遭受较年夜挑衅,所需投进本钱数额宏大。若何以可复制可反复原则再开辟在产油田,更经济高效地开辟难度更高的新油田是石油行业广泛面对的挑衅。是以下降本钱,进步决议计划效力,快速进行,主动化,下降风险,是能源行业重要存眷点。

本钱下降依附进步质量、交付范畴、以及避免反复工作;优化范畴与需求;晋升油田主动化运营;晋升快速实行才能;进步油田信息传送,以确保更好的决议计划;支撑项目终极退役;支撑投资让渡或吞并等贸易行动;增进合作方与供给商之间的整合

Business model

Upstream Oil and gas industry activities are defined by the following high-level processes (Oil and gas life cycle):

Exploration acquire a production permit and prove the hydrocarbon bearing of the prospect.

Appraisal evaluate the economic suitability of the field.

Development planning develop an integrated plan that will deliver business value in comparison to other options.

Execution - develop the field and design and build the capital infrastructure including wells.

Production produce the hydrocarbons efficiently over the life of the field. Where the value is delivered.

Abandonment, decommissioning and restoration close off the permit.

营业模式

以下归纳综合性的流程(石油自然气性命周期),界说了石油自然气范畴的各类贸易运动

勘察 须要出产允许,并确保足够多的原油(原气)含量以支持贸易运作

评估 评估某油田(气田)的经济价值

制订打算 制订一个相对最优的整体打算,实现贸易价值

履行 扶植开采井以及其他固定举措措施,开采油田(气田)

出产 在油田/气田性命周期内,高效出产原油/原气,这是价值之源

油田/气田的弃置、情况恢复 封闭允许

Adoption of Industry 4.0 elements underpinned by InfoQuickTechnologies.

产业4.0利用点

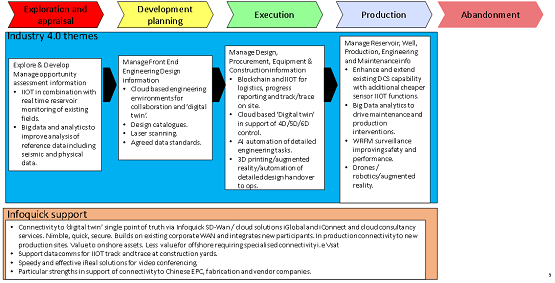

The following outline shows key industry 4.0 Digitalisation themes in upstream Oil and Gas and how InfoQuick Global Connect are positioned to help the oil industry deliver them.

下图展示了产业4.0技巧在石油自然气钻探范畴的利用点

Upstream Industry 4.0 themes and InfoQuick support

As shown by the above slide Oil and Gas companies are actively investing in digitalisation and Industry 4.0 strategies to meet their business objectives. InfoQuick are well positioned to support these strategies. It is worth examining some of these key strategies in more depth:

IIoT and the Mesa working group. This industry working party has produced a process industry guidebook Adopting Integrated Manufacturing Operations Management (iMOM) in oil and gas and petrochemicals framework. The document provides complete guidance on industry best practice relating to digital transformation and Industry 4.0 practices specific to the Oil and Gas industry.

Big Data analytics in combination with IIoT and sensors (PLMs). Increased data capture and analysis designed to detect performance issues and potential well or facilities issues before they impact production. InfoQuicks offerings can provide Wide Area Networking support for these solutions in a nimble, secure, flexible and global way.

Automation in production. The opportunity to automate thousands of wells spread across regions (a large company handles more than 50,000 wells). InfoQuick SD-Wan and cloud capabilities support these solutions through cheap provision of connectivity to a high level of quality in a manageable way.

Supply chain integration and automation of related processes including improved data sharing through management of a Digital Twin. InfoQuick SD-Wan and cloud capabilities support these solutions and allow for new entrants into the supply chain in a quick and cost effective across the globe.

Improved exploration and reservoir monitoring. Advancements in seismic data acquisition (4D, micro-seismic) and computing power have already improved EP companies understanding of reservoirs and ability to monitor constantly. InfoQuick SD-Wan and cloud capabilities support these solutions.

Digital twin. A virtual copy of the evolving plant or oil facility through design, construction and as built in operation. A variety of vendor tool sets available often cloud based to manage this requirement. Actively used, the Digital twin underpins 4D/5D/5D planning and automatic sequencing of construction activities. InfoQuick retain knowledge of the processes and systems used to manage the digital twin.

Convergence of traditional Scada /DCS systems with Industry 4.0 technologies. The traditional suppliers to the oil industry such as Honeywell are converging with commodity IIoT / IoT technologies. InfoQuick have arrangements with process control providers to assist clients.

以上展示了产业4.0技巧若何助力该范畴的企业在每个阶段到达其贸易目的,辅助企业告竣以下要害性计谋价值。而凌锐蓝信确保每个阶段,多场景下的平安、高可用、灵敏机动、高机能、可散布式安排的低本钱收集衔接。

产业物联网与Mesa 工作组。这个组织曾经编写过一本行业领导书在石油石化自然气范畴,采取整合型制作运营治理架构。这本书完全地论述了产业4.0与数字化在行业内的最好实践

年夜数据与产业物联网传感器的共同。进步数据捕捉,且经由过程剖析模式探测终极成果是否有题目,或在出产受影响之前,找到有潜伏题目的油井。这些体系间的互操纵与互动性,离不开平安且高机能的广域网衔接。而凌锐蓝信应用第三代SD-WAN技巧确保这些互动之间的收集平安与机能

主动化出产。这项技巧可以让企业同时出产上千个油井装配,以便快速安排(至公司经常可以处置跨越5万口井)而凌锐蓝信可以辅助企业获得出产进程须要的低本钱,高可用的收集衔接

供给链与主动化过程的整合,包含数字孪生带来的更高效的数据分享过程。凌锐蓝信DT-WAN技巧与相干云连通与迁徙才能,可以轻松支撑这类场景,并让新介入公司平安快速地融进过程

晋升勘察与油储监控。高机能盘算才能已经让行业内企业提前获取地动数据(4D,微地动)并由此懂得储油量。iCONNECT 可以辅助企业轻松应用云盘算而下降盘算本钱

数字孪生。一种涵盖工场及举措措施全性命周期的虚拟数字拷贝,用来设计建造,模仿真实运营。良多供给商的相干东西都在云平台上,SaaS模式。数字孪生可以支撑4D/5D/6D 打算制订以及主动将建造行动排序。凌锐蓝信有才能支撑企业经由过程高机能收集应用这种东西

将传统Scada/DCS体系整合进产业4.0系统。传统供给商如霍尼韦尔,正在进行IIoT/IoT相干整合计划,凌锐蓝信早已预备好,助力相干企业客户。

(编辑:王林)